ABOUT US

Our Brand Story

The journey of Elastin started in 1933 as JPC Elásticos, S.A, which was one of the first to recognize the market potential in 1960’s and became the first elastic band manufacturing company in Portugal. Strong business experience and know-how recognized over the past 84 years, integrated with a new leadership and partner team, built Elastin in 2017.

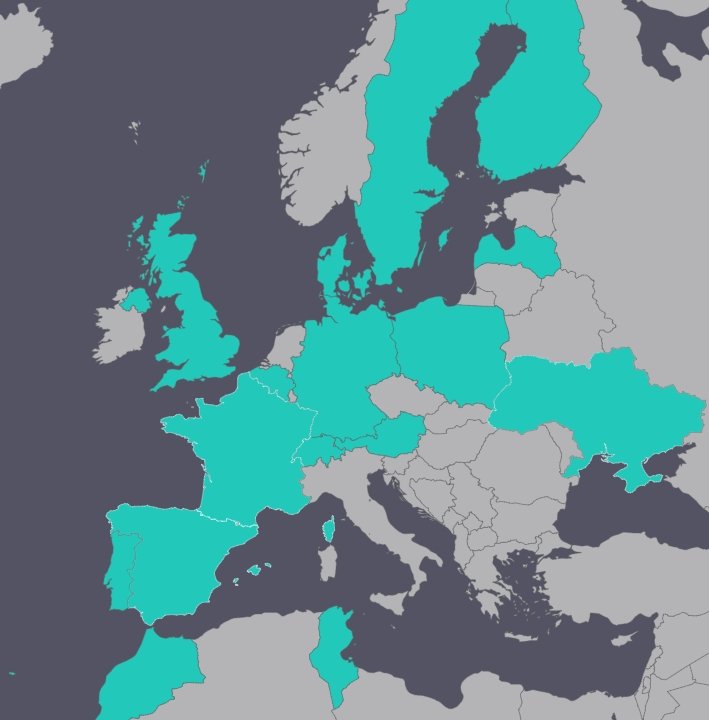

We provide a reliable and fast service throughout the world for products of elastic bands for lingerie, medical elastics such as surgical mask elastics, sportswear and underwear using modern technologies and advanced weaving, dyeing resources backed up by a department focused to quality control. Every day we are expanding our sales network in more than 20 countries and have an export share of over % 50.

Our company is located at the intersection of the main access routes to the city of Oporto, on an area of approximately 10.000m2 in Valongo and are equipped with all the technical and logistical requirements to use our industrial capacity to its full length. Our production processes take place in Porto through collaboration with our strong suppliers, selected on their technical experience capacity level and qualified certifications.

Our professional team guarantees commitment to our clients’ work we undertake every day and our management team’s main aim is always assisting and meeting our customer’s needs. We are fully integrated and focused into the entire production chain which guarantees the prompt customer-service, highest quality and flexibility to different requirements.Our Network

- Denmark

- Portugal

- Latvia

- Finland

- Ukraine

- Poland

- Belgium

- Spain

- France

- Morocco

- Germany

- Tunisia

- Austria

- Switzerland

- Norway

- Sweden

- Netherlands

- United Kingdom

OUR PRODUCTION

COVERING, WARPING AND WEAVING

This is a vertically organized industrial section which looks after the covering of the elastomer and the warping and weaving processes. It is equipped with the latest industrial version with different lines of weaving, crochet and jacquard looms.

Our well-qualified and multi-skilled technical workforce carries out complex tasks during three daily shifts in accordance with industrial process best practices.

This unit is lean, well-controlled and effective, and benefits from appropriate industrial layout and software planning and control tools aimed at obtaining top class results and fully satisfying our clients’ needs.

We have a sample service fully dedicated to responding to complex technical challenges and to the speed required by the fashion market. This unit also provides expert support to the marketing team.

DYEING & COLORING

The mission of this department is the coloring and hot-pressing of the elastic ribbons. It has modern machinery, a specialist workforce and the support of a color section for the storage of colorants, the handling of dye recipes, the preparation of dips and the checking process, with the use of auxiliary technical resources.

This unit dedicates technical ad human resources to the development of new color samples and meeting requests for limited quantities for collections, thus contributing in a decisive manner to the commercial success of our clients.

It provides effective laboratory support, particularly in the formulation of recipes, guaranteed for specialized techniques using a spectrophotometer and a data base containing information on all operations carried out to date.

QUALITY

The Quality Team simultaneously looks after “Product Management”, the process of internal monitoring of all the order execution phases, making sure that all quality and service requisites contracted with the client, particularly delivery times, are satisfied.

The guaranteeing of final quality is thus a process involving the successive verification of the technical conformity of the product.

This process includes checking of the raw materials, control of the recipe and the prescribed technical procedures for covering, warping, weaving and dyeing of the elastic, the laboratory tests and the systematic inspection of the final product before dispatch.

PACKING

Our team pack the elastic in the best way, using a zigzag distribution system and packaging which facilitates the use of the elastic in garment manufacturing lines. A spool process can also be used.

Our packaging system is done as external cardboard packing or plasticization of box pallets, depending on the volume and the destination of the shipment.

PRODUCTS

WOMEN'S LINGERIE

We have numerous technical capabilities, highly segmented and well-established offers for women lingerie; bra, underwear, korset, brif and stockings through our vertical production structure.

MEN'S UNDERWEAR

We shape men underwear products for an elegant and trendy look with ease and comfort by using modern technologies and advanced jackard products.

SPORTSWEAR

Sportswear is a real trend in our daily life’s which is driving a lot of sophisticated elements like special yarns, printed /jacquard weaving resources.

MEDICAL PRODUCTS

Our medical products are combination of special raw materials produced by our experienced team using high technologies. We mainly aim the comfort and well- being of the users during the treatment process.

CERTIFICATION

The STANDARD 100 by OEKO-TEX® is a worldwide consistent, independent testing and certification system for raw, semi-finished, and finished textile products at all processing levels, as well as accessory materials used.

With its decades of experience, the OEKO-TEX® Standard 100 contributes to high and effective product safety from a consumers point of view. Test criteria and limit values in many cases go far beyond applicable national and international standards. Extensive product checks and regular company audits also ensure that the industry has a globally sustainable awareness of the responsible use of chemicals. With this concept, the OEKO-TEX® Standard 100 has taken on a pioneering role for many years.

As Elastin, we can produce under OEKO-TEX® Standard 100 certification upon requirement and we are taking the health and safety as our first priority for our consumers.